Introduction

Instances of the same component within an assembly can be controlled individually to have the state changed, the configuration swapped or the instance replaced with a new component.

This article shows how to replace instances with a new driven replacement model.

How it works

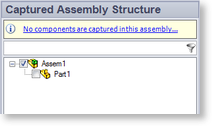

When an assembly contains identical components, with identical names, they are given instance numbers in the SOLIDWORKS feature manager (<1>, <2>, etc.). When viewing the captured assembly structure for the assembly in DriveWorks only the seed component will be available for capture.

This is ideal for assemblies where the instances will always remain identical in every new assembly generated by DriveWorks.

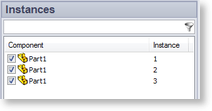

When each instance is to be driven independently the seed component should not be captured as a child of the assembly. Instead each instance should be captured using the Instances feature.

When driving the configuration or state of each instance this is all that is required as far as capturing is concerned. But when the instance is to be swapped with a new component a component and it's parameters that are to be controlled must be captured outside of the assembly.

Example - Capture the Information

An assembly ( Assem1.sldasm) contains 3 instances of the same part ( Part1.sldprt). These parts are driven to different sizes each time a specification is made.

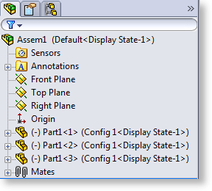

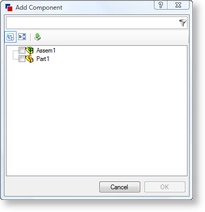

The structure of the assembly in the SOLIDWORKS feature manager looks like this:

To set up this assembly to control the instances individually:

- Capture the assembly in DriveWorks. (open the assembly in

SOLIDWORKS and select the "Click here to capture the active

model" helper link.)

- Capture the parts as instances in the assembly. (select the

instances button then select all the instances that are required)

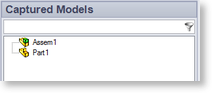

- Capture the part as a component outside of the assembly. (Open

the part in SOLIDWORKS and select the "Click here to capture

the active model" helper link.)

- Capture the parameters of the part that require to be controlled.

Example - Add the components to the DriveWorks Project

With all the capturing done we are now ready to add the components to the project in DriveWorks Administrator.

- Open or create a project to use for this example.

- Select Stage 4. Output Rules > Model Rules from the task explorer.

- Click Add to add the components to drive.

- Select the Assem1 assembly and the Part1 part, click OK.

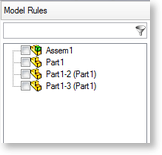

- Click Add again to add another occurrence of Part1, click OK.

- Repeat step 5 for as many occurrences that can replace

instances in the assembly.

DriveWorks will automatically rename each other occurrence -2, -3, etc. in the Model Rules section. Only the reference to the occurrence is changed, this does not rename the actual SOLIDWORKS file.

Example - Build rules for the components

With all the components added, rules can be built that will enable each instance to be swapped with a new driven component.

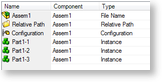

- Select all occurrences of Part1 from the model list so their

parameters are shown in the main window.

Note DriveWorks has automatically built the rule for the File Name parameter of each occurrence ( DWSpecification). This is acceptable, but as the rule will result in the same file name for each occurrence this will not generate different files.

- Select the file name parameter for the first occurrence and click Build to launch the Rule Builder.

- Add the text

& "-1" to the existing rule. This will create

a file name based on the DWSpecification number with -1 added.

- Select the file name parameter for the second occurrence and click Build to launch the Rule Builder.

- Add the text & "-2" to the existing rule. This will create a file name based on the DWSpecification number with -2 added.

- Repeat steps 5 and 6 for all other occurrences, each time incrementing the number to be added to the file name.

- If any other parameters (dimensions, features, etc) have been captured for the components build the rules for them now.

- Next select

Assem1 from the model list so the parameters are

shown in the main window. Note the instances are listed with other

parameters from the captured assembly.

- Select the first instance of the component to be replaced and click Build to launch the Rule Builder.

- Select the Components tab on the right hand side of the Rule

Builder and double click the Part the first instance is to be

replaced with, Click OK to apply the rule and close the Rule

Builder.

- Select the second instance of the component to be replaced and click Build to launch the Rule Builder.

- Select the Components tab on the right hand side of the Rule Builder and double click the Part the second instance is to be replaced with, Click OK to apply the rule and close the Rule Builder.

- Repeat steps 10 and 11 for all other occurrences, each time selecting a different occurrence from the components tab.

Example - Component Ordering

The final step is to ensure the components are generated in the correct order.

Models are built in the order they appear in the model list. When an assembly is found DriveWorks will generate all base level children first and work up to the top level parent.

The use of driven replacement models to replace instances in an assembly dictates that the replacement models should always be generated (if required) before the assembly they are to be replaced into.

If the model list shows the Assem1 at the top:

- Select the Assem1 from the model list.

- Click Move Down to move the Assem1 component down in the order

You now have all the information required to successfully replace instances of the same component with new files that are different.

Information <Replace>

The <Replace> function in DriveWorks removes the need to know the File Name result of the replacement model.

When a rule is applied to the file name parameter of a component, selecting that component from the components tab of the rule builder will automatically use the file created.

- Welcome

- What's New

- DriveWorks 23

- Older Versions

- DriveWorks 22

- DriveWorks 21

- DriveWorks 20

- DriveWorks 19

- DriveWorks 18

- DriveWorks 17

- DriveWorks 16

- DriveWorks 15

- DriveWorks 14

- DriveWorks 12

- What's New DriveWorks 12

- Form Design

- Rule Builder

- Model Rules

- DriveWorks Add-in for SOLIDWORKS

- SP1

- SP2

- DriveWorks 11

- Welcome to DriveWorks Solo 11 What's New

- Capturing

- Project Designer

- Installation

- Licensing

- SP1

- SP1.1

- SP2

- SP3

- V10

- V9

- V8

- SP0

- SP1

- SP2

- SP3

- V7

- Before You Begin

- Using DriveWorks Solo

- DriveWorks Solo Inside SOLIDWORKS

- Enabling the DriveWorks Solo Add-ins in SOLIDWORKS

- Project Wizard

- Capturing Models

- Captured Models

- Part Mode

- Assembly Mode

- Drawing Mode

- Run

- Run (Layout Mode)

- Project Designer

- Project Designer

- Stage 1: User Interface

- Stage 2: Data and Rules

- Stage 3: Output Rules

- Writing Rules

- Writing Rules

- Rules Builder

- Extract Variable

- Edit Variable

- Rule Builder Settings

- Document Rules

- Model Rules

- Model Rules Overview

- Parts and Assemblies

- File Name

- Relative Path

- Configuration

- Feature

- Dimension

- Tolerances

- Custom Property

- Instance

- File Formats

- Advanced Feature Parameter Rules

- Model Rules Advanced Feature Parameter Rules - Overview

- Boss/Base Features

- Boss/Base Thin

- Break Corner

- Chamfer

- Circular Component Pattern

- Circular Pattern

- Coordinate System

- Cosmetic Thread Features

- Curve

- Curve Driven Pattern

- Curve Through XYZ Points

- Cut Features

- Distance Mate Features

- Draft

- Edge Flange

- Features

- Fillet

- Hole Wizard Features

- Linear Component Pattern

- Circular Pattern

- Linear Pattern

- Lofted Bend

- Mates

- Mold Features

- Offset Surface

- Pattern Driven Component Pattern (Derived)

- Patterns with Advanced Feature Parameters

- Revolved Boss/Base

- Revolved Boss/Base Thin

- Rib

- Ruled Surface

- Sheet Metal Features

- Simple Hole

- Sketch Driven Pattern

- Slot Mate

- Surface Features

- Sweep Thread

- Table Driven Pattern

- Var Fillet

- Weldment Features

- Wrap

- Drawings

- Functions

- Functions

- Conversion

- Cryptography

- Date and Time

- File System

- Helper

- Lambda

- List

- Logical

- Math

- Specification

- Table

- CountIF

- CSVFromTable

- Dcount

- DMax

- DMin

- DWHLookup

- DWVLookup

- GetTableValue

- HLookup

- ListAll

- ListAllConditional

- ListAllConditionalDistinct

- ListAllDistinct

- SumTableColumn

- TableAppendColumns

- TableAppendRow

- TableAppendRows

- TableAverage

- TableBreak

- TableColumn

- TableColumnLookup

- TableCombine

- TableDistinct

- TableDistinctCount

- TableDistinctSum

- TableFilter

- TableFilterAll

- TableFilterByList

- TableFormat

- TableFromCsv

- TableFromList

- TableGetColumnCount

- TableGetColumnIndexByName

- TableGetDataRows

- TableGetHeaderRow

- TableGetRowCount

- TableGetRows

- TableGetValue

- TableJoin

- TableMax

- TableMaxValue

- TableMin

- TableMinValue

- TableRemoveBlankColumns

- TableRemoveBlankRows

- TableRemoveColumn

- TableRemoveRow

- TableReplaceHeaderRow

- TableReplaceHeaders

- TableReplaceRow

- TableReverse

- TableRow

- TableSearch

- TableSelectColumns

- TableSequence

- TableSkipRows

- TableSort

- TableSortByDate

- TableSortByList

- TableSubstitute

- TableSum

- TableTakeRows

- TableTranspose

- TableWithSequence

- VLookup

- Text

- Validation

- Variables

- Knowledge Base

- Concept

- How To

- How To: SolidWorks Best Practices

- SOLIDWORKS Best Practices (KB13103019)

- SOLIDWORKS Features

- How To: Correctly Format Text

- How To: Backup a Project (KB13022601)

- How To: Change A Static Property To A Dynamic Property (KB13111201)

- How To: Create A Cut Down Project (KB17092602)

- How to: Create and Install Project Templates

- How To: Determine the Version of DriveWorks Solo

- How To: Diagnose Project Issues

- How To: Diagnose Project Issues Using On Demand Generation Report

- How To: Diagnose Project Issues Using The Form Designer

- How To: Diagnose Project Issues Using The Rules Builder

- How To: Diagnose Project Issues Using SOLIDWORKS

- How To: Drive the Color of a Part (KB12121016)

- How To: Drive the Material of a Part

- How To: Drive the Texture of a Part (KB13103010)

- How To: Find DriveWorks Solo License Keys

- How To: Implementation Guide

- How To: Reference Control Properties (KB16010601)

- How To: Rename a Project

- How To: Replace a Component With a Static or Driven Replacement Model

- How To: Replace An Instance With A Driven Replacement Model

- How To: Maintain Rules For An Existing Model When It Becomes A Child Of A Parent Assembly

- SOLIDWORKS Best Practices (KB13103019)

- How To: Troubleshoot Licensing

- How To: Troubleshoot WebView2 Runtime Installation (KB25102401)

- How To: Work With Arrays

- How To: Use Filters (KB15111101)

- Info

- Form Control Properties

- Color

- Border Style

- Border Width

- Button Layout

- Caption, Text (Appearance Property)

- Caption Horizontal Alignment

- Button and Caption Width

- Character Limit

- Check Alignment, Option Alignment

- Checked

- Check Size, Radio Size, Button Icon Size, Toggle Size

- Clear Selection Allowed

- Decimal Places

- Default Value

- Display Value

- Enabled

- Error result

- File Name

- Font

- Height

- Hide Characters

- Hover, Text Underline

- Hyperlink

- Button Icon Style

- Increment

- Inset Track

- Input Spacing

- Items

- Left

- Link Behavior

- Maximum

- (Metadata)

- Minimum

- Multiline

- Name

- Number Of Rows

- Opacity (Disabled)

- Orientation

- Override Rule

- Padding, Input Padding, Unit Padding

- Picture

- Picture (Checked), (Hover), (Selected), (Pressed)

- Picture Size Mode, Size Mode

- Picture Style

- Placeholder Text

- Border Radius

- Read Only

- Reverse Direction

- Selected Item

- Selected Item Removed Behavior

- Show Border

- Show Check, Show Option

- Show Limits

- Show Toggle Indicators

- Size Mode

- Tab Index

- Tag

- Text Horizontal Alignment, Toggle Alignment

- Text (Label Control)

- Text, Value (Behavior Property)

- Text, Vertical Alignment

- Thumb Height

- Thumb Image

- Thumb Image Size Mode

- Thumb Margin

- Thumb Padding

- Thumb Width

- Tooltip Duration

- Tooltip Text

- Top

- Track Color

- Track Color (Fill)

- Track Fill Start Value

- Track Size

- Visible

- Width

- Word Wrap

- File and Template Locations

- Info: DriveWorks File Extensions (KB13022602)

- Info: File and Template Locations (KB13103001)

- Template Files

- Lists and Preferences

- Reporting

- Help File

- General Information

- Info: Dangling Dimensions

- Info: Distributing A Solo Project

- Info: DriveWorks Solo Limits

- Info: Instant3D

- Info: Keyboard Shortcuts (KB13103004)

- Info: Known Issues (KB13103005)

- Info: Legal Notices

- Info: Microsoft .NET September 2022 Update Crash (KB22101401)

- Info: Mirrored Components

- Info: SOLIDWORKS System Options (KB12121012)

- Info: Special Variables

- Info: Supported DriveWorks Versions (KB13103006)

- Info: Third Party Information And Downloads

- Info: Microsoft Windows Support (KB13010803)

- Info: Working With SOLIDWORKS Enterprise PDM

- Glossary