Introduction

DriveWorks has been developed with Ease of Use in mind. The

intention and practise at most companies is that Engineers can

implement DriveWorks for themselves.

DriveWorks Solo is an add-in to SOLIDWORKS that is used to

implement and run your products.

This document provides guidance on getting started with

DriveWorks Solo and provides guidance on maintaining an

implementation going forward.

Using DriveWorks

There are three elements to every DriveWorks Solo

Implementation:

Setting

upSetting up a DriveWorks implementation requires SOLIDWORKS and

DriveWorks Solo and will always involve the following:

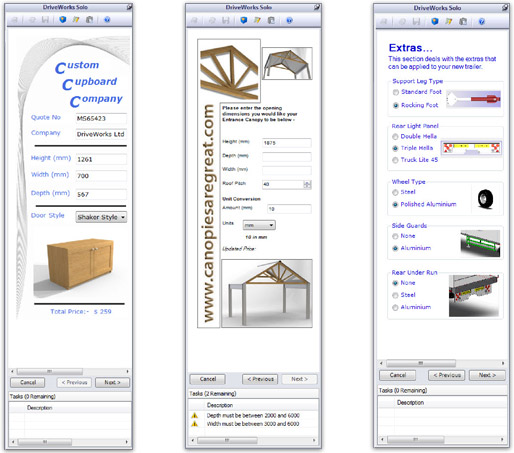

- Creating the user forms that will be used to capture the

requirements of each product that will be automated. (See

Form Design)

- Applying rules for the display of data and behavior of the

controls on the user forms.

- Capturing and applying rules to 3D CAD models and 2D drawings

that will be used as templates for the CAD output. (See

Task Pane)

- Capturing and applying rules to documents that will be used as

templates for any documentation outputs. (See

Documents)

Running a DriveWorks implementation is using the user forms,

from within the SOLIDWORKS task pane, to capture the customer

requirements of the product.

Once the user forms have been used in this way the data entered

is referred to as a specification.

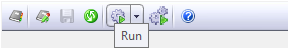

DriveWorks Solo offers two ways a project can be run

| Icon | Run Method | Description |

|---|

| Run Project | - Opens the forms to specify the DriveWorks Solo Project

|

| Run Project in Layout Mode | - Requires an assembly to be active in SOLIDWORKS

- Opens the forms to specify multiple variants and insert them

into the active assembly.

|

Generating the outputs that are required from a specification is

done from the DriveWorks Solo task pane inside SOLIDWORKS.

Generation can be done by the following methods:

Who Implements DriveWorks?

The most successful DriveWorks cases are those where a

DriveWorks Champion is appointed from within the company. The

DriveWorks Champion should be:

- Knowledgable about the product or products

being automated

- SOLIDWORKS proficient

Training

DriveWorks Solo training is essential to establish a good

understanding of DriveWorks Solo.

Only the personnel responsible for implementing your products in

DriveWorks Solo need training.

DriveWorks

offers FREE online training - click here to see the topics

covered- Lesson 1: Model Capture

- Lesson 2: Project Designer

- Lesson 3: Building Rules

- Lesson 4: Running your Project

- Lesson 5: File name and Relative Path Rules

- Lesson 6: Replacing Files

- Lesson 7: Tables

- Lesson 8: Form Navigation

- Lesson 9: Improving Your Forms

- Lesson 10: Driving Replacement Files

- Lesson 11: Controlling Custom Properties

- Lesson 12: Documents

- Lesson 13: Controlling Drawings

Implementation Plan

Regardless of the Implementation Method selected the steps

involved in setting up a DriveWorks implementation generally

follow:

1. Decide

on the product to be automated.Selection of the first

product to automate is critical.

Don’t select the simplest

product, or the most complex, but do take into account the most

time consuming at the current time (without automation) while

factoring in how many of these products are produced. In short,

which product do you spend most time producing.

When automating CAD models,

next ask yourself if it is worth automating a subset of models

first. This is particularly relevant for large and often very

complex assemblies and may not be necessary for smaller, easier to

manage assemblies.

If one particular area, of

the selected product, currently takes a larger portion of time to

design then that may be a good starting point.

Now is the time to create a New

Project to begin building the user forms.

Tip Box

| The

Create Project Wizard also allows data created with

DriveWorksXpress to be imported into DriveWorks Solo. |

Creating the User Forms

Before automating the design of this first product, we recommend

taking time to create the user interface, even before the models

are captured in DriveWorks.

Creating a user interface can help define the assembly structure

of your models for scalability and flexibility going forward. It

will also help with defining the information required on any

documentation required and structuring any data that is to be

used.

Don’t spend too long at this stage on making the user forms look

nice, or setting up the Error Result properties to indicate invalid

data, these can be addressed later. Also controls can be cut and

pasted onto additional forms at any point, so form navigation is

not very important at this stage (unless there are an exceptional

large amount of form controls from the outset).

Project Structure

Creating the user forms will also help define the project

structure within DriveWorks.

The project structure will develop with the implementation, so

do not be overly concerned with this for now but the project

structure will dictate:

- If all products will be specified through a single project

- If separate projects are required for each product

Once the User forms have been created, the next step is to

capture the master templates that will be used to automatically

generate the required outputs.

The master templates could be SOLIDWORKS models that will

ultimately create manufacturing or sales drawings.

DriveWorks will always create the native

file the captured template, from here additional file

types, that are required as deliverables, can also be automatically

generated.

Tip Box

| At this

stage just be aware of the deliverable outputs that will be

required. Concentrate on creating the native templates

first. |

The chart below lists the most

common additional file that can be produced from

the native template file.

*Other additional file formats can be produced

automatically.

| Native Template File Type | Common additional file formats that can be produced from the

template |

|---|

| SOLIDWORKS Assembly | eDrawing, JPEG, PDF, DXF |

| SOLIDWORKS Part | eDrawing, JPEG, PDF, DXF |

| SOLIDWORKS Drawing | eDrawing, DXF, DWG, PDF |

Create the native templates

You may already have SOLIDWORKS models and drawings that can be

used as templates to be automated. If so the chances are you have

taken advantage of some SOLIDWORKS functionality designed to make

manual manipulation of the models quicker. Be aware that these

types of features do not necessarily mean things will be easier

with full blown design automation. Our guide

How To: SOLIDWORKS

Best Practices highlights the areas to look out for.

Additionally adding complexity to the models in the form of

In-context (top down) design or equations only serves to slow down

model generation and makes maintaining the implementation more

difficult. We always recommend capturing the design intent firmly

in DriveWorks.

Assemblies

If the structure of how the product is assembled is already in

place capture the top level assembly.

If the structure of how the product is assembled is not yet

defined or could change then capture a sub set of components that

will ultimately form part of the top level assembly. DriveWorks

allows for changing top level assembly structures. More information

can be found in the article

How To: Maintain Rules For An Existing Model When It Becomes A

Child Of A Parent Assembly

Drawings

Drawings are an essential part of design automation as they are

invariably required to manufacture or even sell your product.

As drawings are a by product of 3D models being produced for now

just create a drawing with the required part or assembly detailed

on it. Capture this to the corresponding model.

At this point do not worry about drawing scale or if the views

or dimensions overlap. Do not even worry about populating the

drawing borders or including notes. This can be done later once you

are confident the model on the drawing is doing what is

required.

What we mean here is data that already exists in text files and

spreadsheets. Data that can be of use to DriveWorks, this can be

anything from tolerance tables to pricing information, from product

matrices to stock lists.

Spreadsheets

Spreadsheet information can be copied and pasted into DriveWorks.

Formatting of the data table is essential to make good use of the

data in DriveWorks. The data can be re-copied at any

time if it has been modified or it can be edited directly in

DriveWorks.

The topic

Define

Tables has more information on the types of tables that

can be created in DriveWorks.

Creating the Rules

Now is the time to create rules that will link through from the

user forms to drive the models.

Rules are used throughout DriveWorks. This is not just limited

to the parameters captured from the templates to be driven, but can

be used on form controls to dynamically change appearance, layout

and behavioral properties (see

Form Design).

Rules can decide which forms are shown (see

Form Navigation)

and even instigate a process the specification will take.

When building rules the DriveWorks

Rules

Builder is used. The rules builder provides rules insight

to help with rule construction, links to make use of data,

constants and variables created in the project and useful help and

diagnostic feedback to ensure the rule is valid and equates to the

result you expect.

Tip Box

| DriveWorks will automatically assign a

special variable to name the critical files to be produced. This is

an auto-number that will be appended to the template file

name. At this

stage do not be concerned with how your automatically generated

outputs are named or stored. It is better to leave this until the

content of the outputs are to your satisfaction. |

At this point we should just be concerned with applying rules

that will drive any data on the user forms and the parameters

captured from the required template outputs.

Rules can be applied directly to any Captured parameter or

Dynamic form control property, but if the same rule is

used elsewhere it is better to create it as a variable.

Make as much use of Variables (see

Define Variables)

as you can, as this will give the most flexibility going

forward. Do remember however to categorize your variables to

make them easier to work with.

The topic

Common Functions lists the

functions DriveWorks provides for rule building.

DriveWorks Solo has extensive in-built testing and diagnostics to help verify

the work you have implemented. The ultimate test will come by

running sample specifications through and generating the outputs

automatically, but the majority of inaccuracies can be

identified during the setting up of the implementation.

The areas that can be tested effectively without generating

outputs are as follows:

- User Interface - The general functioning of each

individual user form and the controls on it can be tested using the

Test button in the form designer.

- Data and Rules - Variables calculate in real time,

as long as any form control used in any rule has a valid

value.

- Output Rules - All output rules calculate in real

time, as long as any form control used in any rule has a valid

value.

Additionally DriveWorks Solo produces reports post model generation. These indicate what was done to each model generated and if it was successful or not.

This can be a fun exercise and will make your

implementation appealing for colleagues to use and provide a

greater level of automation in the outputs. Plus if you have

followed the advice above, you are already benefitting from a good

level of automation.

User forms - Follow these tips for enhancing the forms your target

audience will use

- Ease of use - Think about how easy the forms are to use. Does

the information presented flow? Can the user TAB between controls?

Are there to many controls on a single user form?

- Bad Data - Don't allow invalid data to be entered. Apply

form warnings (or even labels with a bold red font!) to verify data

that has been typed into the control by the user. Make good use

of DriveWorks Validation functions (see Validation Functions

in

Common

Functions) to verify if the user has inadvertently entered any

characters that will make subsequent rules fail.

- Captions - Do the captions on controls stand out? Controls with

common properties can be multi-selected to apply fonts that stand

out.

- Labels - Use labels to apply section headings when specifying a

particular part of the product. Or use them to provide the user

with feedback.

- Pictures - Make good use of the picture control to make the

forms visually appealing. Picture controls are not only great for

showing an image of what is being specified (Create JPEG images

from your SOLIDWORKS models), but can be used to display company

logos. Decorative borders and section lines to divide areas of

interest can also be shown.

- Hide Controls - Any controls that are no longer needed consider

using the visible property (set to FALSE) to hide the controls

rather than delete them. Consider placing controls that hold

similar information, but are opposing in display state, on top of

each other to retain the users focus to the same area.

Documents - Tidy the document templates up

- Apply company logos

- Ensure the content is formatted correctly

- Remove any highlighting used to distinguish driven values

Drawings

- Sort out overlapping views

- Set the scale

- Apply the notes

- Fix the dimensions

- Hide dangling dimensions

- By now you should have a good feel for which annotations and

dimensions need controlling through DriveWorks. You should be

getting to the point where you are comfortable with the output and

the only reason you are opening each drawing is to tidy it

up. Automating annotations and dimensions should reduce if

not eliminate this need.

Names - Adopt your preferred naming conventions.

- Models - DriveWorks identifies models that have previously been

generated by the file name of each assembly and part. For a model

to be generated it must have a name that has not been used

previously. DriveWorks automatically assigns the special variable

DWSpecificationID to each captured model which guarantees a unique

number will be applied to the generated model. The article

Concept: File

Naming discusses the methods that determine how this can

be applied. Now is the time to decide which models will always

require to be generated and which models will become standards.

Standard models require a intelligent naming convention, this could

simply be applying the results of the changing parameters to the

name, applying a part number stored in a custom database, or

adopting a coded part number using lookup tables formatted in the

project.

- Drawings - For a drawing to be created each time it's parent

model must also be created. DriveWorks automatically assigns the

special variable DWSpecification to each captured drawing, which

means the name of the Specification will be applied to the

generated drawing. The article

Concept: File

Naming discusses the methods that determine how this can

be applied. If the file name parameter for a drawing has no rule it

will take the name of it's parent model.

- Documents - Documents do not require a unique name to be

generated, but will require a unique folder for them to

be stored (otherwise any existing documents will be overwritten by

the new one). The same methods discussed in

Concept: File Naming are used

for documents.

File Paths - Get the outputs stored where you want them.

All outputs will be stored in the Results folder, unless the result of the rule for the Relative Path parameter of any output is an absolute path (for example - G:\DriveWorks\Alternative Generated Outputs).

Where the result of the rule for the Path parameter of any output is relative (for example ON123\Models) and the location does not exist DriveWorks will create it.

- Models - Models do not require a unique folder to be created.

DriveWorks automatically assigns the special variable

DWSpecification to the Relative Path parameter. This will result in

the Specification Name parameter being applied to the Default

specification folder setting. When using a Standard naming

convention for models it is good practice to place these models

into a "Standards" folder (or a sub folder of this location)

- Drawings - Drawings do not require a unique folder to be

created. DriveWorks automatically assigns the special variable

DWSpecification to the Relative Path parameter. This will result in

the Specification Name parameter being applied to the Default

specification folder setting. If this parameter has no rule the

drawing will be stored with the parent model.

- Documents - Documents do not require a unique folder, but will

require a unique name for them to be created (otherwise any

existing documents will be overwritten by the new one). By default

the Output File Path rule is left blank, this will create the document

in the Specification Path folder.

- Reports - Reports are stored in the Results folder and are given a unique name and relative path. This cannot be changed.

The process of telling DriveWorks Solo that a feature,

dimension, model, or some other entity should be controlled by

DriveWorks Solo.

A value controlled by a rule.